Cask and packaging washing system

- Function: Handling casks and packing which have hazardous wastes, and recycling them into new casks and packaging to be provided to the units which have the demand for use.

- Capacity: 350 kg/h.

- Treatable wastes: all sorts of packaging, iron casks, plastic casks,1m3 tank, all sorts of tanks.

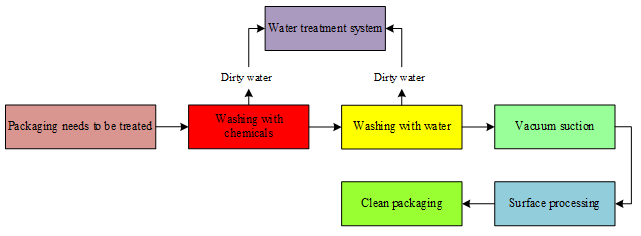

- Treatment process:

+ All sorts of packaging (cask, plastic or iron cans, etc.) after collected from the release sources will be gathered into the warehouse. The chemicals in packaging will be thoroughly got out by absorbing thanks to sawdust or sucking thanks to rags. The sawdust and rags will be terminated in incineration.

+ Afterward, the packaging are washed with chemicals: The bigger-size packaging for iron or plastic casts will be washed in the centrifugalbarrel finishing machine, chemicals such as solvents and detergents are put into the packaging with the crushes (used for iron balls, or sharp things) to wash inside packaging, and we can wash the smaller packaging by hands. After washing with chemicals and crushes, we use a pressure pump to wash the packaging again thanks to the water from the pump. The packaging after washed clearly with water will be sucked vacuum, and dry the inside surface of packaging. The outside surface of packaging are carefully crushed with a manual crushing machine to make sure that the stamps of packaging must be cleaned and washed later. The deformed packaging will be shaped to assure the aestheticism of packaging. The packaging after treated will be used as a packaging or for sale to the units who have the demands for use.