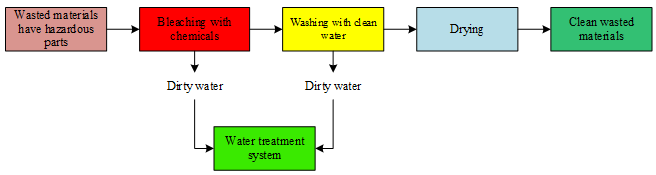

System of plastic, metal soaking, bleaching and washing

- Function:bleaching and washing the sorts of wasted materials which have hazardous parts. The clean wasted materials will be sold.

- Capacity:1,500 kg/h.

- Treatable wastes: metal, wasted materials have hazardous parts.

- Treatment process:

+ The wasted materials which have hazardous parts will be bleached in each patch. At the bleaching zone, the wasted materials are put into the tank and covered, then undergo the following steps:

• Bleaching at the soaking tank with chemicals: using Palang to lift up the barrel and put it down into the tank to be bleached with chemicals; and pumping gas into detergent tank must be regularly made within 20 minutes. Before getting the barrels out, we have to lift up and put down the barrel in the bleaching tank at least 3 times with enough bleaching solution so that oil and hazardous wastes are split away from metal. Periodically, we must add the bleaching solution to the tank.

• Bleaching in tank with clean water: after the barrels are soaked in the chemical tanks, use Palang to hook the barrels and lift up the barrels and put them down into the clean water tank in order to make sure that pumping gas into water tank is regularly made.

• Drying: craning the barrel in place for drying. When water in barrel is off, we lift up and unlock the barrel, gather clean wasted materials in the stipulated place.

• The water which has the solution used for bleaching oil and fat, and clean water will be handled at the clean water treatment system.